Зимняя шина Continental ContiIceContact 2 является следующим поколением одной из самых популярных моделей именитого немецкого производителя. Как и в прошлый раз, его специалисты предпочли пойти более трудным путем, предпочтя заняться разработкой новинки «с нуля». Данная модель использует лишь часть технологий, применявшихся в шине предыдущего поколения. Такой подход позволил существенно улучшить большинство эксплуатационных характеристик, начиная от сцепления на льду и заканчивая топливной экономичностью.

Новая система шипования

Введенные несколько лет назад в европейских странах требования к зимним шинам поставили их производителей перед непростым выбором — ограничить количество шипов, либо использовать их любое количество, но за счет снижения агрессивности их воздействия на дорожное полотно. Специалисты Continental AG предпочли второй вариант, разработав новую систему шипования, которая была названа Kristal Stud.

Бережное отношение к дорогам обеспечивается за счет небольшого размера шипов и оптимизированной формы их твердосплавной вставки. При этом их количество возросло более, чем в полтора раза. У некоторых типоразмеров протектор располагает 190 шипами, вместо 130 у модели предыдущего поколения. В сочетании с их расположением в 18 продольных рядов вместо 9 у предшественницы, контакте с дорогой одновременно максимального количества этих стальных элементов, а также многогранной формой самих твердосплавных вставок это позволило существенно улучшить продольные тяговые характеристики на обледенелом покрытии. Немецкий производитель заявляет о 10-процентном сокращении тормозного пути на льду. Кроме того, нельзя не отметить использование для более надежной фиксации шипа в протекторе специального клеящего состава. В своей обновленной версии он способен удерживать шип при нагрузке до 50 кг. Это в 4 раза больше, чем у шины предыдущего поколения.

Обновленный состав резиновой смеси

Не менее масштабным изменениям подвергся и состав компаунда. Производитель заявляет о появлении в нем полутора десятка новых компонентов. Одним из них являются новейшие полимерные соединения, придавшие резиновой смеси, а значит и самому протектору целый ряд уникальных физико-химических свойств. Прежде всего, это оптимальная эластичность, остающаяся на практически неизменном уровне в очень широком температурном диапазоне, включая показатели, на несколько десятков градусов ниже «нуля». В условиях реальной эксплуатации данная особенность проявляется в виде очень стабильных сцепных свойств при любых дорожных и погодных условиях. Кроме того, с их помощью обеспечивается целостность протектора при эксплуатации во время оттепелей или смены сезона.

Превосходные тяговые характеристики на снегу

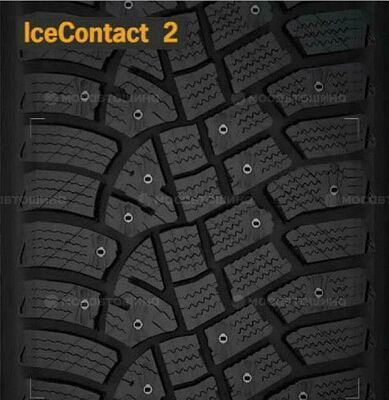

Как и многие другие компоненты шины Continental ContiIceContact 2, ее протекторный рисунок также был разработан заново. Ключевым нововведением его дизайна является увеличение количества отдельных блоков, чего удалось добиться, уменьшив их в размерах. В сочетании со значительным расстоянием между всеми элементами протектора это заметно улучшило тягово-сцепные характеристики на снегу.

Специальные «ледяные кармашки»

Протектор этой шины содержит множество миниатюрных элементов, улучшающих те или иные эксплуатационные свойства. Одним из них являются так называемые «ледяные кармашки». Они расположены в местах установки шипов. Их основным функциональным назначением является измельчение и отвод ледяной крошки от области контакта твердосплавной вставки с поверхностью дорожного полотна. Это препятствует ее налипанию на шип, что, в свою очередь, улучшает сцепление шины на льду.

Несколько видов ламелей

Следующей особенностью дизайна протектора этой шины является использование нескольких видов ламелей. Это обусловлено стремлением разработчиков придать этим элементам различную функциональность, а самой шине — универсальные характеристики.

В частности, в центральной части протектора располагаются ламели, которые при контакте с дорогой блокируются не только своими стенками, но и сами между собой, что существенно ограничивает не только поперечную, но и продольную подвижность блоков. Это заметно улучшает курсовую устойчивость и оперативность управления шины.

В свою очередь, у ламелей в плечевых зонах протектора блокируются только их стенки, что ограничивает подвижность блоков только в поперечном направлении. С одной стороны это повышает эффективность при торможении на скользких покрытиях, а с другой — улучшает устойчивость и сцеплении при маневрировании и в поворотах, а также обеспечивает более высокую устойчивость протектора к неравномерному износу.

Кроме того, в плечевых зонах протектора имеются специальные продольные ламели. Эти элементы создают так называемый «кромочный эффект», благодаря которому шине придается дополнительное сцепление и устойчивость при совершении маневров на скользких от дождя, снега и наледи дорогах.

Основные особенности шины Continental ContiIceContact 2

- почти две сотни шипов образуют в процессе движения 20 непрерывных рядов, что в сочетании с оптимизированной формой их твердосплавных вставок обеспечивает надежное и стабильное сцепление на льду;

- фиксация шипов в протекторе при помощи специального клеящего состава минимизирует риски их преждевременной потери;

- специальные «ледяные кармашки» в местах установки шипов измельчают и отводят от них ледяную крошку, что улучшает сцепление на обледенелом покрытии;

- оптимальная эластичность в очень широком диапазоне температур, отличная устойчивость к высокотемпературному воздействию обеспечивается за счет оптимизированной резиновой смеси с рядом новых компонентов;

- разработанный заново асимметричный протекторный рисунок с увеличенным количеством блоков обеспечивает отменные тягово-сцепные характеристики на снегу;

- несколько видов ламелей улучшает целый ряд основных эксплуатационных характеристик, начиная от сцепления на льду и заканчивая устойчивости и управляемости при маневрировании и в поворотах.

Увеличить

Увеличить  Увеличить

Увеличить  Увеличить

Увеличить

Приблизительный расчёт.

Сумма кредита от 2 000 до 300 000 рублей.

Первоначальный взнос от 0% до 90%.

Срок кредита от 3 до 36 месяцев.

Процентная ставка рассчитывается индивидуально.

Подробнее